Industrial Equipment & Machinery:

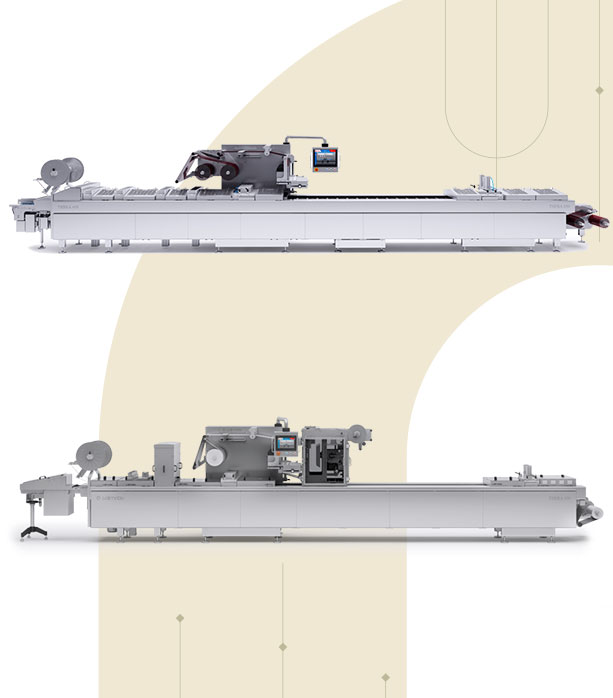

Thermoforming packaging is a complete packaging process able to produce its own trays, in shapes and dimensions tailored to the customer needs utilizing MAP technology at the same time. Thermoformers are most suitable for large production in a variety of aspects such as hygiene, package size, capacity, and is used in all rigid, semi-rigid ,flexible and skin packaging applications.

- Machine length: Customized

- Machine width: up to 1200mm

- Machine height: up to 2000mm

- Loading area: Customized

- Bottom film width: up to 660mm

- Top film width: up to 640mm

- Max advancing index: up to 1100mm

- Pack max depth: up to 220mm

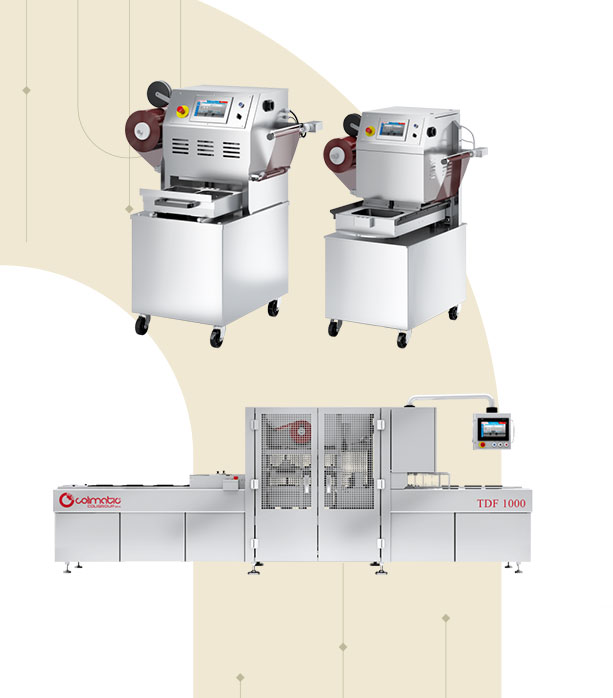

Automatic traysealing for packaging all sorts of food products in pre-made trays suitable for medium production capacities performing seal, vacuum, modified atmosphere (MAP) in gas flush or vacuum+gas as well as SKIN. This flexible packaging machine, with its modular structure, can also be equipped with several sealing stations simultaneously, considerably increasing the output capacity.

- Max tray dimensions: 480mm * 275mm

- Lid applicator

- Tray de-nesting system

- Multiple de-nesting system

- Dosing unit for liquid and creamy products

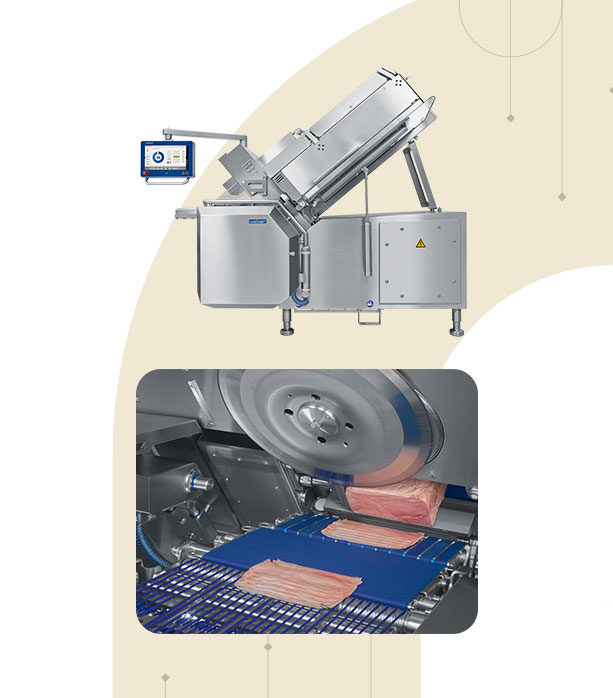

Automatic Slicers guarantee a high output for slicing all sorts of bulk sausages and processed cheese rolls/blocks. The machine is configured individually for the respective product width. Rolls infeed is manual and rapid, even with short length products. Manual and automatic loading onto the packaging machine are available as options.

- Slicing speed (rpm): 600

- Product throat height (mm): 120/135/150

- Product throat width (mm): 330

- Product length (mm): 1200

- Slicing system: Circular blade (optional: involute blade)

- Cutting thickness (mm): 0.5-50

- Loading: (automatic/manual)

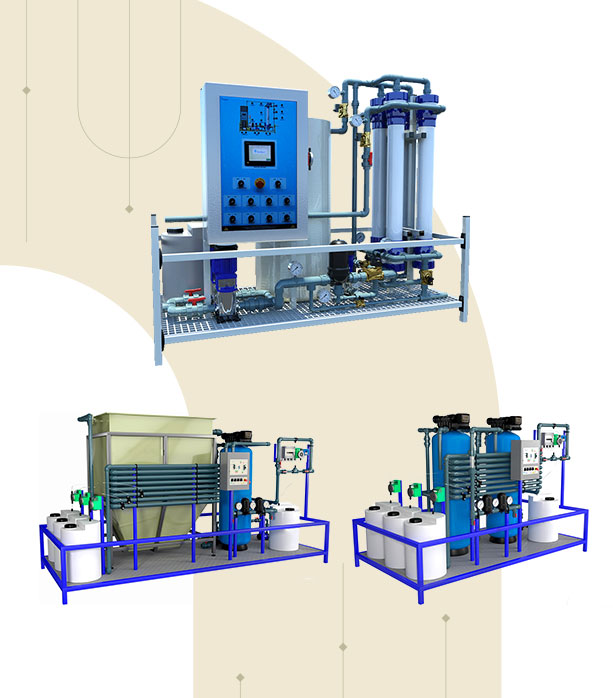

We engineer, procure and construct customized industrial and drinking water treatment plants for every need or destination.

Drinking Water treatment

- Water purification plants for water with low pollutant load through filtration

- Water purification plants through filtration with organic matter load

- To treat low quality surface water with high turbidity

- Decalcification

- Denitrification

- Water demineralization

- Iron removal or water remineralization

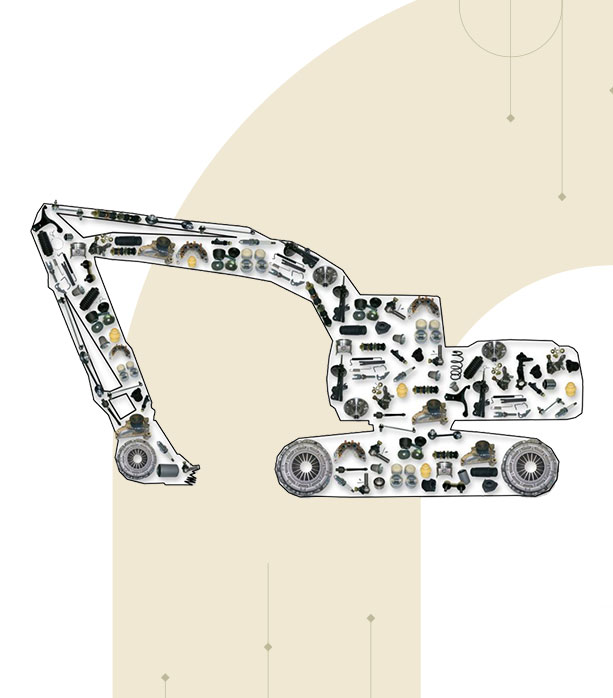

Spare Parts & Accessories:

We offer industrial customers various possibilities for managing their procurement and end-to-end maintenance, repair and operations supply chains in cost-effective ways.

- Significant costs savings by benefiting from a dedicated spare parts procurement service

- Optimized resources and less burdens caused by managing spare parts supply

- Sourcing of parts at the manufacturer of the original equipment, machines or parts

- Negotiated vendor prices and guaranteed lead times

- Longer-term agreements with fixed prices